It is installed in the high pressure section between the condenser and the evaporator. In the newer systems it is built-inside the condenser.

The receiver drier serves three main functions:

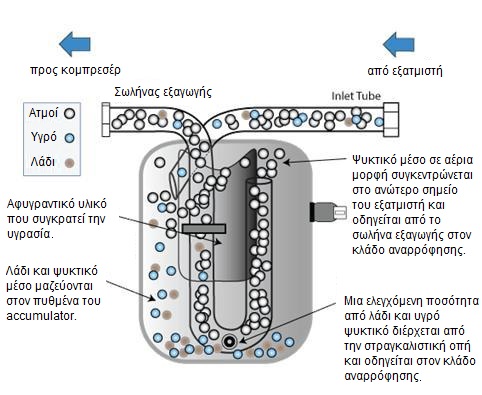

- It stores the refrigerant and the lubricant. For this operation it is very crucial the design of the filter, its size and its correct positioning. Its replacement with a different one can lead to the deterioration of the air condition. The refrigerant from the condenser passes through the filter and the desiccant and then it is stored in the receiver dryer. If during the process of the condensation part of the refrigerant has not liquefied, the vapor is led to the upper part of the filter since it is lighter, while the liquid settles in the bottom from where it is later led to the expansion valve. In this way it is ensured that only liquid refrigerant reaches the expansion valve, where it is expanded absorbing heat during gasification.

- It filters filters dirt and debris that may be circulating in the circuit during the operation of the air condition. For this reason the filters contain a material with small pores that withhold any material tha contaminates the refrigerant.

- They trap the moisture that is trapped in the circuit. For this reason they contain a desiccant XR3, XR5, XR7 or XR9 that absorbs and traps the moisture.

The receiver drier must be replaced regularly because as time passes its porous filter may get blocked from the materials it withholds or the desiccant that it contains my saturate losing its ability to absorb moisture.

In any case its delayed replacement can lead to increased wear because:

- The limited refrigerant flow leads to poor lubrication of the compressor.

- Saturation leads to the existence of moisture in the system. A direct consequence is the corrosion of parts of the air condition and the deterioration of the lubricant which when it absorbs moisture loses it lubricating ability downgrades.

HellasSITES

HellasSITES