In vehicles there is a normal annual loss of refrigerant that could be up to 10%. With timely and correct maintenance of your air condition has maximum performance. Additionally, you enjoy cleaner and healthier air because during maintenance purification is performed killing the developed bacteria and with the timely replacement of the pollen filter it is ensured that there is no growth of microorganisms, bacteria and fungi. Simultaneously you save time and money as wear is prevented that could lead to compulsory replacement of parts.

At ILEP- CryoTech we specialize at the maintenance of air conditioning units for

- Passenger vehicles original equipment and after market

- Trucks

- Vehicles for people transportation, minivans and coaches

- Construction and special application machinery at the clients’ site

But also for refrigeration units for transporting perishable goods

- Chillers

- Freezers

Procedures followed during the maintenance of air conditioning units and refrigeration units:

At ILEP- CryoTech we follow certified procedures for the reliable maintenance of your air condition. We maintain records of all works performed thus achieving the prevention of malfunctioning and the ability to deal with any problem that arises.

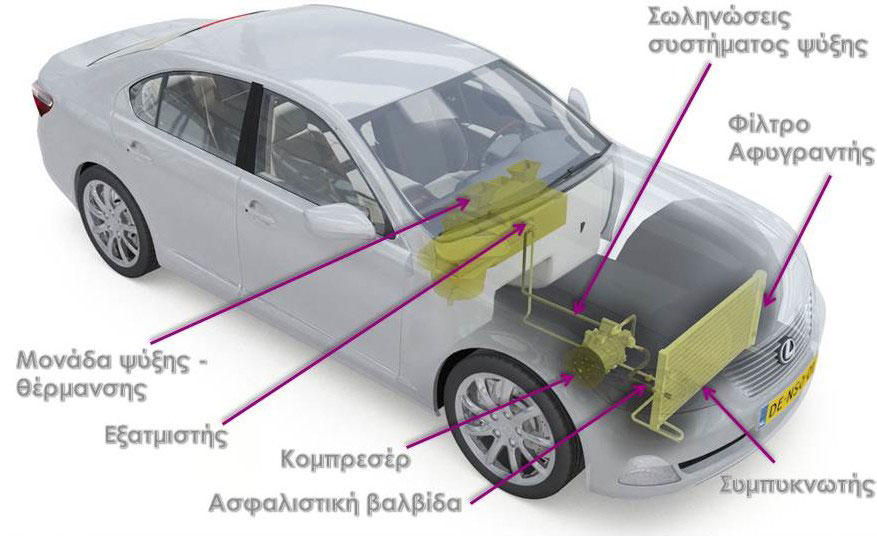

We ensure the correct charging of refrigerant (R134a and HFO1234yf) that is essential for the proper functioning of your air condition. An incomplete charge is responsible for poor performance, increased consumption and inadequate lubrication as the lubricant mixes with the refrigerant. When the compressor is not properly lubricated, the it is susceptible to increase wear that can lead to extensive wear and its replacement which is expensive. During the service the right amount of refrigerant and lubricant is added, which is essential for the system.

We evaluate the overall condition of the system by measuring the amount of refrigerant and checking the quality and condition of the lubricant.

We check the pollen filter for its condition. It is important to regularly replace it because dust, harmful germs, bacteria and fungi accumulate on it during the air conditioning operation. Once saturated the passengers inhale all these harmful substances. The air conditioning performance is reduced when the filters are blocked with dust as the air cannot pass through the evaporator. In addition the reduced flow of air can lead to wear of the fan due to overheat.

We upgrade the performance of the system thoroughly cleaning the condenser resulting to the improvement of the operational by reduced high pressure of the air condition that has a direct impact to the economic and efficient operation of the unit. We check the condition of the receiver drier for saturation or blockage that can ruin the compressor and the expansion valve.

We prevent failures and leakages by visually inspecting the condition and position of the piping protecting the pipes from the surface friction with the fixed parts of the vehicle. In that way we can first of all achieve economy as we prevent the replacement of parts and more importantly protect the environment as the refrigerant is responsible for the greenhouse effect.

You may read further information regarding your vehicle’s heating system here.

*In case you air condition smells unpleasantly do not hesitate to ask our technicians in our work shop to disinfect your vehicle’s air conditioning system.

- Automotive air conditioning system -

HellasSITES

HellasSITES